-

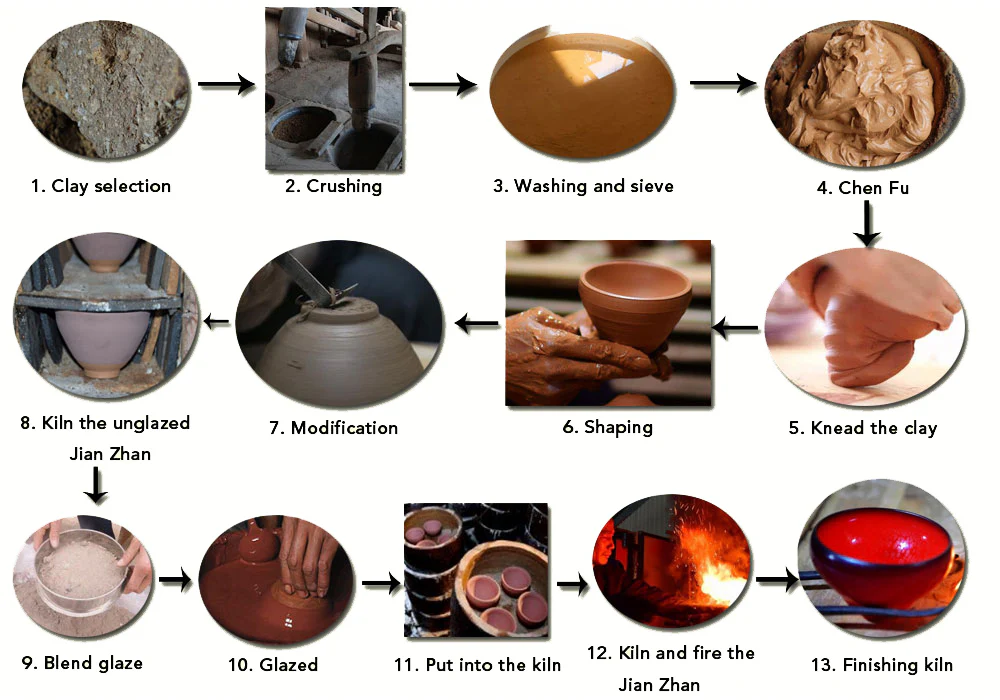

Clay Selection

The glaze and clay of Jian Zhan need to have high iron content. Other kilns from the Song Dynasty tried to imitate Jian Zhan but usually failed because the minerals in their geographic location couldn’t meet the standards required for making Jian Zhan. -

Crushing

The prepared clay and glaze are placed in a machine for pulverization. -

Washing and Sieving

The thickness of the clay or glaze should be moderate. After sieving, the clay needs to be placed into the slurry tank, while the glaze is placed into the glaze pool. -

Chen Fu

Chen Fu is a ceramic term that refers to placing the clay in a room away from sunlight and air, maintaining a certain temperature and humidity, and storing it for a while. -

Kneading the Clay

This process further removes air and impurities from the clay, making it dense and uniformly humid. This helps with shaping and prevents cracking or drying during post-production. -

Shaping

Shaping is typically divided into hand shaping and machine shaping. -

Modification

The traditional shape of Jian Zhan mainly has a shallow circular foot. The base part and the “inner ring” of the foot need to be modified using a knife. -

Kilning the Unglazed Jian Zhan

This process strengthens the mechanical properties of the clay and removes cracked or fragile Jian Zhan pieces in advance. -

Blending Glaze

The glaze formula used in the ancient method combines natural iron ore glaze and plant ash. These two simple substances create the beautiful glaze, which, though simple, results in the most mysterious and intricate crystals. -

Glazing

A notable feature of Jian Zhan crafting is the half-glazed technique. Ancient craftsmen would specifically design a glaze line to control the glaze’s range. The glazing process requires skill to ensure the glaze is applied moderately. If too thin, there won’t be enough room for crystal growth, resulting in a less delicate piece; if too thick, the glaze may stick to the bottom. -

Placing into the Kiln

A layer of alumina powder is usually placed at the bottom to prevent sticking. -

Kilning and Firing Jian Zhan

The kiln is the most important step in creating Jian Zhan. If the time, temperature, and reduction frequency are not well-controlled, the desired glaze color will not be achieved. Once the pieces are placed into the kiln, the master must carefully manage the reduction degree and avoid leaving the kiln unattended for long periods. -

Finishing the Kiln

After the firing, due to the limitations of the making process, each kiln will inevitably produce some defective products, which must be handled on-site. Only those that pass the quality inspection can be sold.